Intake Screens

Tee Intake Screens and Drum Intake Screens

Simplify your approach to the design and manufacturing of intake screens for your operation. Concord Screen is the major manufacturer of high quality wedge wire intake screens. Concord Screen custom designs and builds for all types of industrial facilities requiring intake water including nuclear, hydroelectric, coal, gas, oil and chemical plants, pulp and paper mills. And public and private water companies. Concord Screen’s seamless design and build capability saves you the time and hassles of having to coordinate and deal with separate sources, while providing cost-efficiencies as well. Bring your intake screen requirements to Concord Screen for a complete turnkey solution.

Standard & Specially Designed Intake Screens

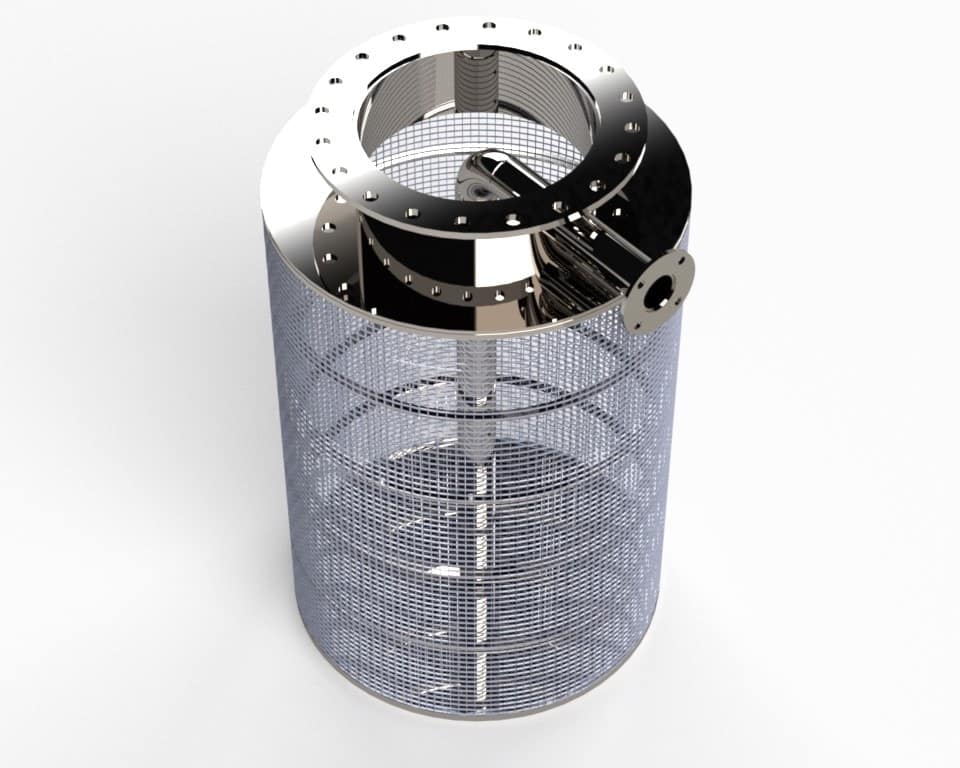

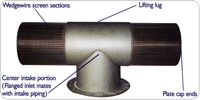

In addition to the screens represented, Concord Screen also fabricates many custom intake screens for unique and difficult applications, from very fine slot sizes to elaborate intermittent flushing units. The Tee Intake Screen is ideal for lake, river, ocean, or pond service. Twin screen ends allow for more uniform patterns across the intake surface. Increased surface area permits screening at very fine slot sizes. The Drum Intake Screen is excellent for low flow rates and general service applications.

Intake Screen Options

Exotic Alloys: To protect against screen binding organisms (such as Zebra Mussels). Also appropriate in corrosive environment applications such as salt water.

Internal Distribution Plates: To provide even flow patterns across the intake screen surface.

Guide Brackets: For rail type installation and service structures.

Diver Door: Provides access for manual servicing of intake screens.

Wedgewire Cap Ends: To further increase screening area where water is stagnant.

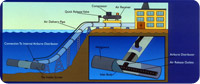

Concord Screen Airburst Assembly©

You can minimize costly maintenance of submerged intake screens with Concord Screen’s Airburst Assembly©. It consists of a surface-mounted air compressor connected to a pipeline to convey air to the intake screen. A quick release valve fires a volume of air approximately three times the screen capacity to the intake. There, an internal airburst distributor transmits the burst of air evenly through the plugged slots of the intake screen to provide thorough automatic cleaning.

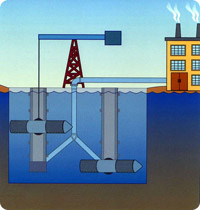

Industrial Intake Screen Suit Any Environmental Application

Concord Screen Intake Screens can be installed in a variety of different patterns, such as the Vertical Slide Rail installation depicted here. Lifting mechanisms are employed with slide rails for convenient removal and maintenance of screens. Cone ends are depicted, facing upstream, allowing the natural current flow of water to sweep any debris from the intake screen. One of the intake screens is being hoisted for cleaning and evaluation. During service, the flow through the embedded pipeline connected to the intake screen in service is temporarily cut off. Interruption of flow to the facility will NOT occur. The remaining inline screen can handle the full flow requirement of the facility, allowing one screen to be removed. Additionally, a lifting mechanism may avoid having a diver go down and clean the screens. Many installations involve the pipeline and intake screen being welded together, making a more permanent application.